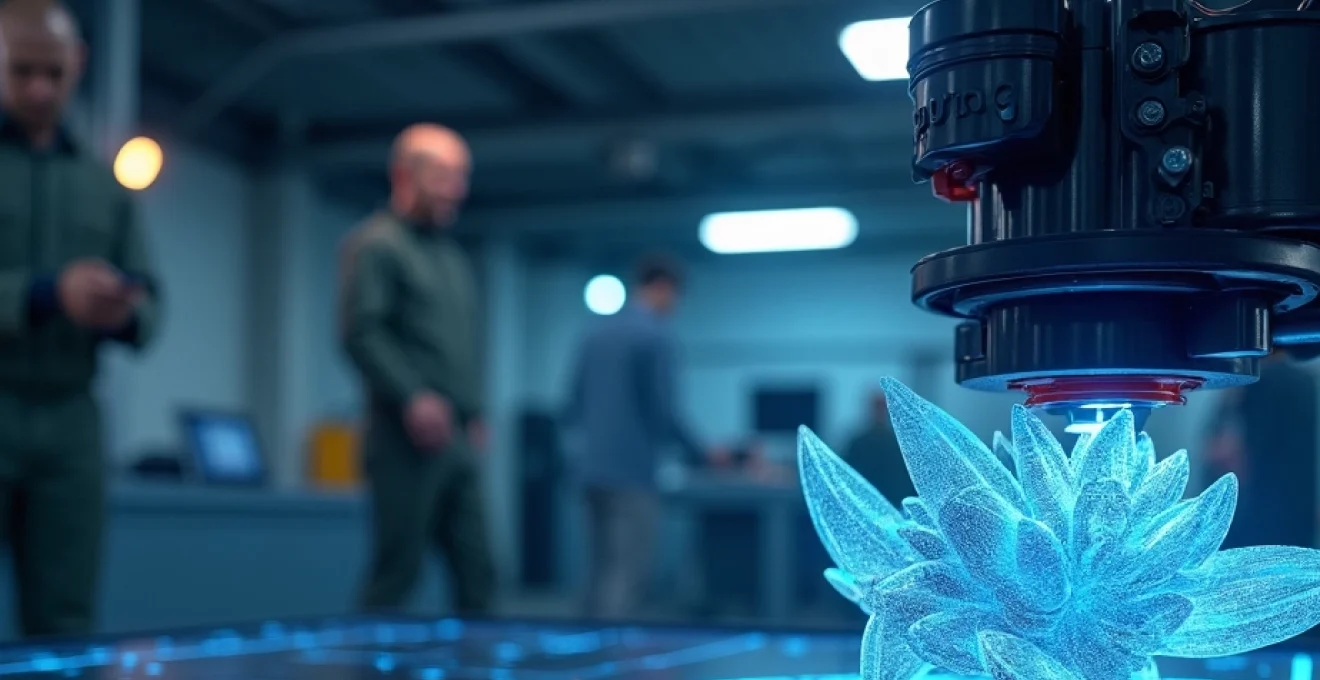

The realm of manufacturing and design is undergoing a profound transformation, driven by the rapid advancement of 3D printing technology. This innovative process, also known as additive manufacturing, is reshaping traditional production methods and opening up new possibilities for creators and industries alike. By building objects layer by layer from digital designs, 3D printing is not only streamlining production but also enabling the creation of complex geometries that were previously impossible or prohibitively expensive to manufacture.

From aerospace to healthcare, automotive to consumer goods, the impact of 3D printing is being felt across diverse sectors. Its ability to produce customised, on-demand parts with minimal waste is challenging long-held assumptions about mass production and supply chain management. As the technology continues to evolve, it’s clear that 3D printing is not just a passing trend, but a fundamental shift in how we conceive, design, and manufacture products.

Additive manufacturing processes in modern industry

Additive manufacturing encompasses a variety of processes, each with its own strengths and applications. Fused Deposition Modeling (FDM), for instance, is widely used for rapid prototyping and producing functional parts. This method extrudes thermoplastic filaments layer by layer to build up the desired object. On the other hand, Stereolithography (SLA) uses a laser to cure liquid resin into solid plastic, offering higher resolution and smoother surface finishes ideal for detailed prototypes and jewellery casting patterns.

Another significant process is Selective Laser Sintering (SLS), which uses a laser to sinter powdered materials into solid objects. SLS is particularly valuable for creating complex, durable parts for functional testing or end-use applications. The versatility of these processes allows manufacturers to choose the most appropriate method based on their specific requirements for material properties, surface finish, and production volume.

Perhaps one of the most exciting developments in additive manufacturing is Metal 3D printing. Techniques like Direct Metal Laser Sintering (DMLS) and Electron Beam Melting (EBM) are revolutionising the production of metal parts, enabling the creation of lightweight yet strong components for industries such as aerospace and automotive. These processes can work with a variety of metals, including titanium, aluminium, and stainless steel, opening up new possibilities for design and performance optimisation.

Material science advancements for 3D printing

The evolution of 3D printing technology has been closely tied to advancements in material science. As the capabilities of 3D printers have expanded, so too has the range of materials available for use. This synergy between hardware and materials has been crucial in driving the adoption of additive manufacturing across various industries.

Thermoplastic filaments: from ABS to PEEK

The journey of thermoplastic filaments in 3D printing began with materials like ABS (Acrylonitrile Butadiene Styrene) and PLA (Polylactic Acid). These plastics offered a good balance of properties and ease of use, making them ideal for early adopters of FDM technology. However, the industry has since progressed to more advanced materials like PEEK (Polyether Ether Ketone), which offers exceptional strength, heat resistance, and chemical resistance. This evolution has enabled the production of high-performance parts suitable for demanding applications in aerospace and medical industries.

Metal powders and direct metal laser sintering (DMLS)

The development of metal powders suitable for 3D printing has been a game-changer for the manufacturing industry. DMLS technology allows for the creation of complex metal parts with properties comparable to traditionally manufactured components. Materials such as titanium alloys, tool steels, and precious metals can now be 3D printed, opening up new possibilities in fields like orthopaedic implants, aerospace components, and customised jewellery.

Biocompatible resins for medical applications

In the medical field, the advent of biocompatible resins has revolutionised the production of dental implants, surgical guides, and hearing aid shells. These materials are designed to be safe for use in the human body and can be precisely tailored to individual patient anatomies. The ability to quickly produce custom medical devices using 3D printing is improving patient outcomes and reducing surgery times.

Composite materials: carbon fibre and kevlar infusions

The integration of reinforcing fibres like carbon fibre and Kevlar into 3D printable materials has led to the creation of parts with exceptional strength-to-weight ratios. These composite materials are particularly valuable in industries where weight reduction is critical, such as automotive and aerospace. By combining the design freedom of 3D printing with the performance of advanced composites, engineers can create parts that are both lightweight and incredibly strong.

CAD software evolution for 3D printing design

The advancement of Computer-Aided Design (CAD) software has been instrumental in unlocking the full potential of 3D printing. Modern CAD tools are not just about creating 3D models; they’re about optimising designs for additive manufacturing, simulating performance, and even automating aspects of the design process.

Topology optimization in autodesk fusion 360

Autodesk Fusion 360 has integrated topology optimization tools that allow designers to create structures that are optimised for strength and weight. By specifying load conditions and design constraints, the software can generate organic shapes that maximise performance while minimising material use. This approach is particularly valuable in aerospace and automotive applications, where every gram of weight saved can translate to significant fuel savings over a vehicle’s lifetime.

Generative design with siemens NX

Siemens NX takes design optimization a step further with its generative design capabilities. This approach uses algorithms to explore thousands of design possibilities based on specified parameters such as material, manufacturing method, and performance requirements. The result is often a set of designs that a human designer might never have conceived, pushing the boundaries of what’s possible with 3D printing.

Cloud-based collaboration using OnShape

OnShape has revolutionised the CAD workflow by offering a fully cloud-based platform. This enables real-time collaboration between team members, regardless of their location. For 3D printing projects, this means faster iteration cycles and easier sharing of designs with manufacturing partners. The platform’s version control and branching features are particularly useful for managing complex projects with multiple design variations.

Industrial applications of 3D printing technology

The industrial adoption of 3D printing has been transformative across numerous sectors. In aerospace, companies like Boeing and Airbus are using additive manufacturing to produce complex, lightweight parts that reduce fuel consumption and improve aircraft performance. The ability to consolidate multiple components into a single 3D printed part not only reduces weight but also simplifies assembly and improves reliability.

In the automotive industry, 3D printing is being used for both prototyping and production. Formula 1 teams, for instance, use additive manufacturing to rapidly iterate and test new aerodynamic designs. Meanwhile, companies like BMW are integrating 3D printed parts into their production vehicles , showcasing the technology’s readiness for mass production applications.

The medical field has perhaps seen some of the most impactful applications of 3D printing. From custom prosthetics and orthotics to patient-specific surgical guides and implants, additive manufacturing is enabling personalised healthcare solutions. In dentistry, 3D printing has become standard practice for producing aligners, crowns, and bridges, improving both efficiency and patient outcomes.

3D printing is not just changing how we make things, but what we can make. It’s enabling a new era of design freedom and functional integration that was previously unimaginable.

In the realm of consumer goods, 3D printing is facilitating mass customisation. Companies are offering personalised products ranging from eyewear frames to running shoes, tailored to individual customer preferences and physical characteristics. This level of customisation was previously only available for high-end, bespoke products, but 3D printing is making it accessible to a broader market.

Rapid prototyping and iterative design processes

One of the most significant impacts of 3D printing has been on the product development cycle. Rapid prototyping has dramatically reduced the time and cost associated with bringing new products to market. Designers and engineers can now quickly create physical prototypes of their ideas, test them, and iterate on the design in a matter of days rather than weeks or months.

Fused deposition modeling (FDM) for concept validation

FDM technology, with its wide range of available materials and relatively low cost, is often the go-to choice for early-stage prototyping. It allows designers to quickly produce physical models to validate form, fit, and basic functionality. The speed and affordability of FDM make it possible to explore multiple design iterations concurrently, fostering a more creative and thorough design process.

Stereolithography (SLA) for High-Resolution prototypes

When higher resolution and finer details are required, SLA comes into play. This technology is particularly useful for producing prototypes that need to demonstrate aesthetic qualities or intricate features. Industries such as jewellery design and consumer electronics often rely on SLA for creating realistic models that can be used for visual evaluation and marketing purposes.

Selective laser sintering (SLS) for functional testing

SLS technology bridges the gap between prototyping and production. The nylon-based materials commonly used in SLS offer good mechanical properties, making them suitable for functional prototypes and even end-use parts. This allows engineers to conduct more meaningful tests on their designs, simulating real-world conditions more accurately than with other 3D printing methods.

Multi jet fusion (MJF) for Production-Ready parts

HP’s Multi Jet Fusion technology has pushed the boundaries of what’s possible with 3D printed prototypes. MJF offers a combination of speed, accuracy, and material properties that make it suitable for producing functional prototypes and low-volume production parts. This technology is particularly valuable in industries where time-to-market is critical, as it allows for rapid iteration and testing of production-ready designs.

Supply chain disruption and On-Demand manufacturing

3D printing is fundamentally changing the dynamics of manufacturing and supply chains. The ability to produce parts on-demand, close to the point of need, is challenging traditional notions of inventory management and distribution. This shift towards decentralised, on-demand production has several significant implications:

- Reduced inventory costs: Companies can maintain digital inventories of parts, printing them only when needed.

- Faster response to market demands: New products can be brought to market more quickly, and existing products can be more easily customised or updated.

- Localised production: Parts can be produced closer to where they’re needed, reducing shipping costs and carbon footprint.

- Simplified supply chains: The number of suppliers and intermediaries can be reduced, streamlining logistics and reducing complexity.

The concept of digital warehouses is gaining traction, where companies maintain a library of 3D printable designs that can be produced on-demand. This approach is particularly valuable for spare parts and low-volume products, where traditional manufacturing and inventory management can be costly and inefficient.

In the aerospace industry, for example, GE Aviation has implemented 3D printing for producing fuel nozzles for its LEAP engine. This not only simplified the manufacturing process by consolidating multiple parts into a single component but also enabled on-demand production, reducing the need for large inventories of spare parts.

The fashion industry is also exploring the potential of 3D printing for on-demand manufacturing. Companies like Adidas are experimenting with 3D printed midsoles for shoes, allowing for customised footwear tailored to individual foot shapes and running styles. This approach not only offers enhanced performance but also reduces waste associated with mass production of standardised sizes.

On-demand manufacturing enabled by 3D printing is not just about efficiency; it’s about reimagining the entire product lifecycle from design to delivery.

As 3D printing technology continues to advance, its impact on manufacturing and supply chains is likely to grow. The ability to produce complex, customised parts quickly and locally has the potential to reshape global trade patterns and bring about a new era of distributed manufacturing. This shift could lead to more resilient supply chains, reduced environmental impact from transportation, and new opportunities for local manufacturing economies.

In conclusion, 3D printing is not just a new manufacturing method; it’s a catalyst for innovation across design, production, and supply chain management. As the technology matures and becomes more widely adopted, we can expect to see continued disruption and transformation across industries. The future of manufacturing is likely to be more flexible, more localised, and more responsive to individual needs than ever before, thanks to the revolutionary potential of 3D printing.