Winter temperatures plunging to -30°C expose critical weaknesses in standard window construction. Heat escapes through invisible pathways, condensation freezes along frames, and energy bills climb while comfort deteriorates. These aren’t minor inconveniences—they’re measurable performance failures that compound year after year in extreme cold climates.

The engineering response to these challenges separates adequate products from exceptional ones. While generic energy efficiency ratings provide baseline comparisons, Canadian windows are designed to exceed those minimums through testing protocols calibrated specifically for sub-zero operating environments. This climate-specific approach addresses thermal performance variables that only become critical when outdoor temperatures remain below freezing for months.

Understanding why these windows perform differently requires moving beyond marketing claims to examine the engineering standards, measurable performance outcomes, and true cost calculations that reveal how climate-specific design translates to long-term value. The distinction lies not in isolated specifications but in systematic optimization across multiple performance dimensions simultaneously.

Canadian Window Performance Essentials

Canadian-manufactured windows undergo rigorous testing for extreme climate zones, addressing performance metrics beyond basic U-factor ratings. These products are engineered to maintain thermal efficiency through freeze-thaw cycling while minimizing heat loss pathways that intensify in sub-zero conditions. The result combines immediate energy savings with extended operational lifespan, creating total cost advantages that justify premium pricing through measurable long-term value.

Engineering Standards Driven by Canada’s Extreme Climate Zone Classifications

Canada’s geography spans climate zones ranging from temperate coastal regions to arctic conditions, creating testing requirements that exceed standard North American protocols. The country’s seven distinct climate zones demand different minimum performance thresholds, with zones 5 through 7 experiencing sustained periods below -20°C. This geographic diversity necessitates more stringent baseline standards than regions with moderate winter conditions.

Since 2020, Canada has adopted a unified ER ≥ 34 or U‑factor ≤ 1.22 W/m²·K requirement for all ENERGY STAR certified residential windows. This single national criterion eliminates previous regional variations, establishing a performance floor calibrated to climate zone 2 conditions while encouraging manufacturers to exceed these minimums for colder zones. The shift reflects recognition that installation proximity to harsh climate testing facilities correlates with product optimization for real-world winter performance.

The regulatory framework distinguishes Canadian manufacturing through technical specificity rather than marketing differentiation. Testing procedures measure not just thermal transmission but integrated performance under conditions that simulate extreme weather exposure over extended timeframes.

CSA A440.2-14 or A440.2-19 Fenestration Energy Performance and/or ANSI/NFRC 100-14 or ANSI/NFRC 100-17 procedures determine product U-factors and Solar Heat Gain Coefficient at Normal Incidence

– Ecoline Windows Technical Team, Ecoline Windows ENERGY STAR Guidelines

These protocols evaluate performance variables under temperature differentials that exceed 50°C between interior and exterior surfaces—conditions that occur routinely during Canadian winters but rarely factor into standard NFRC testing calibrated for moderate climates. The CSA A440 series incorporates air leakage measurements, condensation resistance factors, and structural performance under wind loading as integrated components rather than isolated metrics.

| Standard | Testing Focus | Application |

|---|---|---|

| CSA A440.2-19 | Energy Rating (ER) with air leakage | Canadian residential |

| NFRC 100/200 | U-factor and SHGC primarily | North American commercial |

| NAFS-22 | Structural performance | Wind/water resistance |

Building code harmonization across provinces creates consistency in minimum specifications while allowing municipalities in extreme climate zones to mandate enhanced requirements. This regulatory structure incentivizes manufacturers to engineer products that perform across all seven climate zones rather than targeting minimum compliance thresholds.

Toronto Building Code Harmonization Impact on Window Specifications

CSA A440.3 user guide enables determining Energy Ratings for specific locations and orientations across Canada’s 7 climate zones, with calculations assuming vertical installation and average solar radiation conditions for representative heating degree-days ranging from 4000 to 6200

Manufacturing proximity to extreme climate testing facilities provides continuous feedback loops for product refinement. Canadian manufacturers routinely test prototypes under actual winter conditions rather than relying solely on laboratory simulations, identifying performance gaps that only emerge during sustained exposure to sub-zero temperatures combined with high wind speeds.

Performance Metrics Beyond U-Value: Air Leakage and Thermal Bridging Rates

While U-factor provides a standardized thermal transmission measurement, it represents only one component of real-world energy performance. Air leakage ratings become critical performance indicators in high-wind winter conditions where infiltration rates multiply thermal losses. The A-rating system classifies windows from A1 (tightest) to A3 (standard residential), with each classification representing measurable differences in cubic feet per minute of air infiltration under pressure differentials.

In sub-zero environments, even minor air leakage creates localized cold spots that accelerate condensation and frost formation. A window rated A3 might perform adequately in climate zone 2 but demonstrate problematic infiltration in zone 6 where sustained winds compound pressure differentials. Canadian specifications increasingly mandate A2 or better ratings for northern installations, recognizing that air tightness becomes proportionally more critical as ambient temperatures decrease.

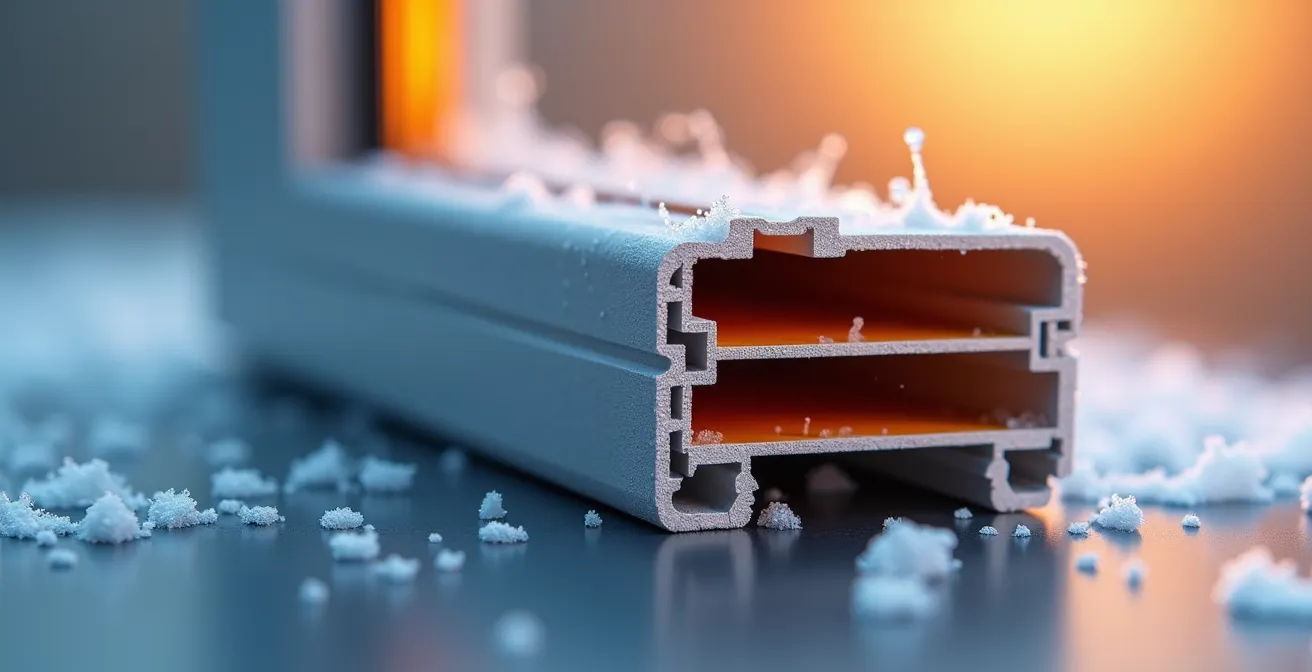

Linear thermal bridging at frame edges represents another performance dimension that intensifies in extreme cold. Standard aluminum spacer bars create continuous conductive pathways between interior and exterior glass surfaces, with thermal transmission rates that multiply when outdoor temperatures drop below -20°C. The temperature differential across these bridges can reach 40°C or more, creating zones where interior surface temperatures fall below dew point despite adequate center-of-glass R-values.

Advanced spacer bar technologies interrupt these conductive pathways using materials with thermal conductivity coefficients one-tenth that of aluminum. The performance improvement manifests most dramatically at edge-of-glass zones, which constitute 15-20% of total window area but can account for 30-40% of heat loss in poorly designed units operating under extreme conditions.

The engineering solution combines warm-edge spacer technology with thermally broken frame designs that physically separate interior and exterior aluminum profiles. This dual-barrier approach reduces linear thermal bridging coefficients from typical values of 0.08 W/m·K to 0.03 W/m·K or lower, delivering measurable improvements in overall window thermal performance that become increasingly significant as window-to-wall ratios increase.

Solar Heat Gain Coefficient optimization for northern latitudes presents counterintuitive requirements compared to cooling-dominated climates. While southern regions prioritize low SHGC values to reduce cooling loads, northern installations benefit from higher coefficients on south-facing exposures to capture passive solar gains during heating seasons. Canadian testing protocols evaluate SHGC at solar angles typical of 45-55°N latitudes rather than standardized perpendicular incidence, recognizing that real-world performance varies with geographic location.

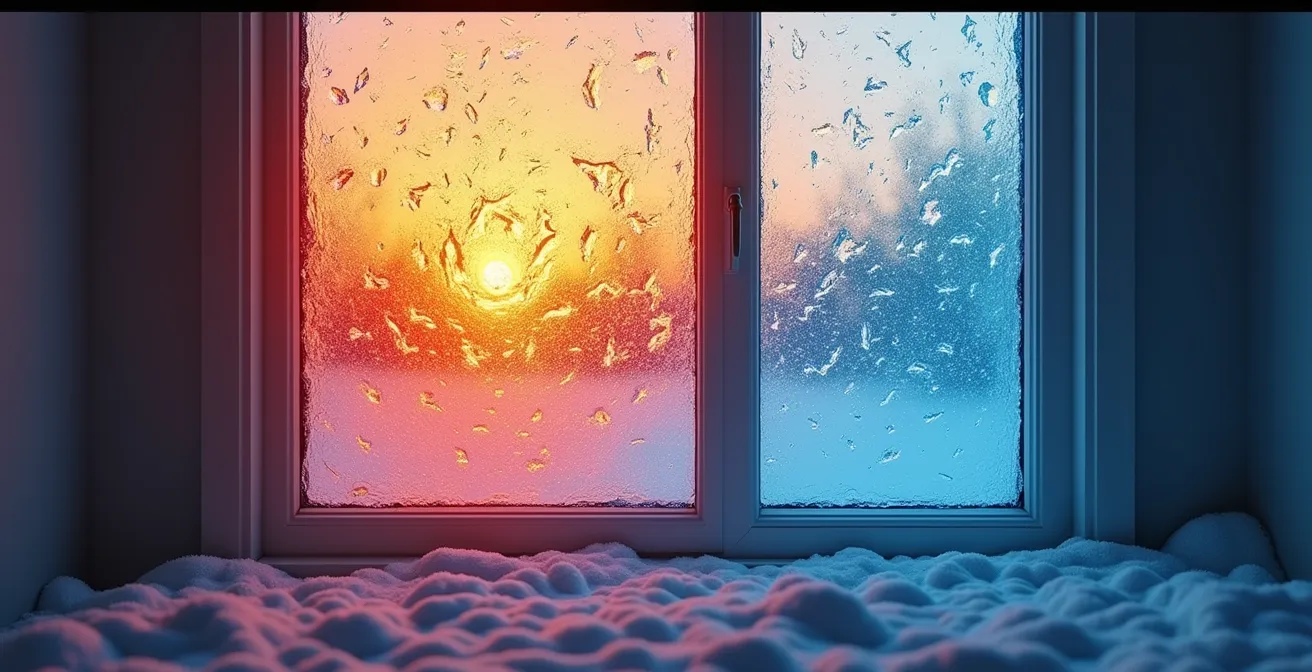

Condensation Resistance Factor requirements address the extreme interior-exterior temperature differentials common in well-insulated Canadian homes. A properly heated interior at 21°C combined with exterior temperatures of -30°C creates 51°C differentials that challenge even high-performance glazing systems. CRF ratings of 50 or higher indicate frames and edge-of-glass zones engineered to maintain interior surface temperatures above dew point under these demanding conditions, preventing the moisture accumulation that degrades seals and frames over time.

Heat Loss Pathways Specific to Sub-Zero Operating Environments

Center-of-glass R-values dominate window performance discussions, but heat loss distribution shifts dramatically in extreme cold. When outdoor temperatures drop below -15°C, edge-of-glass zones transition from minor contributors to primary thermal loss pathways. The thermal gradient steepens at frame-glass interfaces where multiple materials meet, creating localized high-flux zones that account for disproportionate energy transfer.

Edge-of-glass heat loss ratios can reach 2.5 times center-of-glass rates under extreme conditions. A window with excellent center-glass insulation (R-5) but poor edge design might deliver whole-unit performance of only R-3.2 because perimeter zones constitute 20% of total area while contributing 40% of heat loss. This performance degradation intensifies as window sizes decrease, since perimeter-to-area ratios increase in smaller units.

Installation gap performance represents what industry professionals call the “fifth side” of the window thermal envelope. Even perfectly manufactured windows fail thermally when rough openings lack proper air barrier integration and insulation continuity. The gap between window frame and structural opening creates a bypass pathway that allows interior air to contact cold surfaces, generating convective loops that multiply heat loss beyond calculated whole-unit values.

Effective installation requires continuous air barriers that connect interior vapor barriers to window frames without gaps, combined with low-expansion foam or fiberglass insulation that fills voids without creating compression gaps. Approaches centered on reducing home energy consumption recognize these installation details as critical components of overall building envelope performance.

Thermal imaging reveals these bypass pathways as distinct heat signatures around window perimeters, often showing interior surface temperatures 5-8°C cooler than adjacent wall sections. These cold zones indicate air leakage or missing insulation that undermines window performance regardless of glazing quality. Canadian building science emphasizes installation protocols that treat windows as integrated systems rather than standalone components.

Wind-driven air infiltration multiplication factors specific to exposed installations demonstrate why laboratory testing alone cannot predict field performance. A window tested at static 75 Pa pressure differential might achieve A2 ratings, but the same unit installed on a wind-swept 20th-floor exposure experiences dynamic pressure fluctuations reaching 200 Pa during winter storms. These peak loads can temporarily overwhelm weather sealing, creating intermittent infiltration events that substantially increase seasonal energy consumption.

Advanced weather seal designs incorporate multiple sealing planes that maintain contact pressure across wider tolerance ranges. Dual-seal systems position one barrier to block water infiltration and a second to control air leakage, with drainage planes between them to evacuate any moisture that bypasses the primary seal. This redundant approach maintains performance even when individual components experience temporary seal loss during extreme wind events.

Frame Material and Seal Durability Through Freeze-Thaw Cycling Stress

Material selection for extreme climate performance involves understanding how repeated thermal cycling affects structural integrity and dimensional stability. Standard vinyl formulations become brittle below -20°C, with impact resistance degrading by 60% or more at extreme temperatures. A window frame that survives ASTM impact testing at 21°C might crack from routine thermal stress or minor impacts during harsh winters.

Impact-modified PVC formulations engineered specifically for cold climates incorporate elastomeric modifiers that maintain flexibility across temperature ranges from -40°C to +60°C. These enhanced compounds resist embrittlement while preserving structural strength, demonstrating impact resistance at -30°C that exceeds standard vinyl performance at room temperature. The material science advances translate to frames that maintain dimensional stability through hundreds of freeze-thaw cycles without warping or developing operation problems.

Fiberglass composite frames offer coefficient of thermal expansion advantages critical for extreme temperature swings. Standard vinyl expands and contracts approximately 5mm per linear meter across a 60°C temperature range (-30°C to +30°C), while fiberglass composites move less than 1mm across the same span. This dimensional stability maintains consistent weather seal compression and prevents the gap formation that leads to air leakage as materials cycle through seasonal temperature extremes.

The reduced expansion rates also minimize stress on glass edge seals, extending the operational lifespan of insulated glazing units. Repeated expansion-contraction cycling gradually degrades adhesive bonds and compression seals in frames with high thermal movement, creating pathways for moisture infiltration that eventually cause seal failure and glazing unit degradation. Dimensionally stable frames maintain consistent seal compression, significantly extending the timeframe before performance degradation becomes measurable.

The visible comfort differences become immediately apparent during winter months when properly engineered windows maintain interior surface temperatures within 2-3°C of room air temperature even as outdoor conditions reach -30°C. This narrow differential eliminates the cold radiation effect common with lower-performance windows, where occupants feel uncomfortably cool despite adequate air temperatures due to radiant heat loss to cold glass surfaces.

Seal chemistry determines whether weather barriers maintain elasticity and compression force through hundreds of freeze-thaw cycles. Silicone formulations retain flexibility across extreme temperature ranges better than urethane compounds, maintaining effective compression and rebound characteristics that ensure continuous contact between sealing surfaces. Urethane seals may harden and lose recovery capability after extended exposure to sub-zero temperatures, creating permanent gaps that compromise air tightness.

Extended warranty terms of 25 years or more serve as indirect indicators of manufacturer confidence in climate-specific durability testing. These warranties reflect engineering validation that frame materials, seal compounds, and glazing unit construction will maintain specified performance levels through decades of extreme thermal cycling. Shorter warranty periods often signal products optimized for moderate climates where thermal stress remains relatively modest throughout product lifecycles.

Key Takeaways

- Canadian testing standards measure integrated performance under extreme temperature differentials exceeding 50°C between interior and exterior surfaces

- Air leakage ratings and thermal bridging control become proportionally more critical as ambient temperatures decrease below -20°C

- Edge-of-glass zones can account for 40% of total heat loss despite representing only 20% of window area

- Impact-modified materials maintain flexibility and structural integrity through hundreds of freeze-thaw cycles from -40°C to +60°C

- True ROI combines annual heating savings with avoided replacement costs over 25-year operational lifespans

True ROI Calculation: Immediate Energy Savings Plus Longevity Premium

Heating cost reduction calculations across Canadian climate zones reveal substantial differences in annual energy savings. A typical 2000-square-foot home in climate zone 6 with 200 square feet of window area might consume 15-20 kWh per square foot annually for space heating. Upgrading from builder-grade windows (U-factor 0.35) to climate-optimized units (U-factor 0.20) reduces window heat loss by approximately 43%, translating to 1,200-1,600 kWh annual savings on a natural gas heating system.

At current energy rates of $0.12 per kWh equivalent, this represents $144-192 in annual savings per household. Over a 25-year window lifespan, cumulative savings reach $3,600-4,800 before accounting for projected energy cost increases. These calculations assume static energy prices—actual savings typically exceed projections as heating costs rise faster than general inflation.

Avoided replacement costs introduce the second component of total cost of ownership analysis. Standard windows engineered for moderate climates often require replacement after 15-18 years in harsh environments due to seal failures, frame degradation, and operation problems caused by repeated thermal cycling. Climate-optimized windows designed and tested for extreme conditions routinely deliver 25-30 years of service before requiring replacement, eliminating one complete replacement cycle.

The avoided replacement cost for 200 square feet of windows installed at $50-65 per square foot totals $10,000-13,000 in current dollars. Combined with cumulative energy savings, the total economic benefit reaches $13,600-17,800 over the extended service life. This calculation framework reveals why premium pricing of 20-30% for climate-optimized products delivers positive ROI within 8-12 years, with substantial additional value accruing throughout the remaining service life.

Performance degradation curves demonstrate efficiency loss trajectories over time. Standard windows in extreme climates show measurable U-factor degradation of 15-25% after 10-12 years as seals deteriorate and frames warp slightly from thermal cycling. Climate-tested products maintain performance within 5-8% of original specifications after 15 years, sustaining energy savings throughout their operational lifespan rather than delivering diminishing returns as seals and materials degrade.

Resale value premiums and insurance considerations add qualitative benefits that enhance overall value propositions. Home energy assessments increasingly document window performance as factors in property valuations, with climate-appropriate installations contributing to higher efficiency ratings that appeal to informed buyers. Some insurance providers offer reduced premiums for homes with impact-resistant windows rated for extreme weather conditions, recognizing reduced claim risk from wind-driven debris damage during severe storms.

Homeowners seeking to optimize housing costs benefit from comprehensive analysis that extends beyond initial purchase price to evaluate total lifecycle economics. The climate-specific engineering that drives Canadian window performance delivers measurable value through the combination of sustained energy efficiency, extended operational lifespan, and avoided replacement expenses that accumulate substantially over decades of service.

Frequently Asked Questions About Window Energy Performance

What is the CSA A440 standard and why does it matter for window performance?

CSA A440 is a series of Canadian standards that define testing procedures and performance requirements for fenestration energy performance. Unlike basic U-factor measurements, CSA A440.2 incorporates air leakage, solar heat gain, and condensation resistance into a comprehensive Energy Rating (ER) that better predicts real-world performance in extreme climates. The standard matters because it ensures windows are tested under conditions that simulate actual Canadian winter environments rather than laboratory ideals.

How does thermal bridging affect my heating costs?

Thermal bridging creates pathways where heat flows rapidly from warm interior spaces to cold exterior surfaces through conductive materials like aluminum spacer bars or continuous frame members. In extreme cold, these bridges can account for 30-40% of total window heat loss despite representing small percentages of window area. Reducing thermal bridging through warm-edge spacers and thermally broken frames can improve whole-window performance by 15-25%, directly reducing the heating energy required to maintain comfort.

Why do Canadian-made windows last longer than standard windows in cold climates?

Canadian manufacturers engineer windows specifically for freeze-thaw cycling stress that occurs when temperatures swing 50-60°C between day and night or across seasons. They use impact-modified materials that resist cold-temperature brittleness, seal compounds that maintain elasticity through extreme temperature ranges, and frame designs with low thermal expansion coefficients. These climate-specific engineering decisions prevent the premature seal failures, frame warping, and operation problems that plague standard windows subjected to harsh winter conditions over 15-20 year lifespans.

What is an Energy Rating (ER) and how is it different from U-factor?

Energy Rating (ER) is a comprehensive metric used in Canada that combines multiple performance factors including U-factor, solar heat gain coefficient, and air leakage into a single number. Higher ER values indicate better overall performance, with residential windows typically ranging from ER 25 to ER 40 or above. Unlike U-factor which measures only thermal transmission, ER accounts for beneficial solar heat gain and penalizes air leakage, providing a more complete picture of how a window will perform in actual heating-dominated climates.